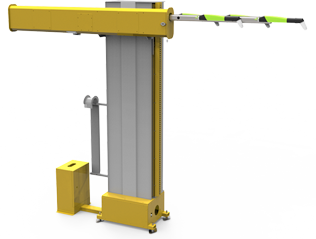

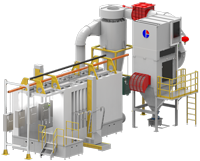

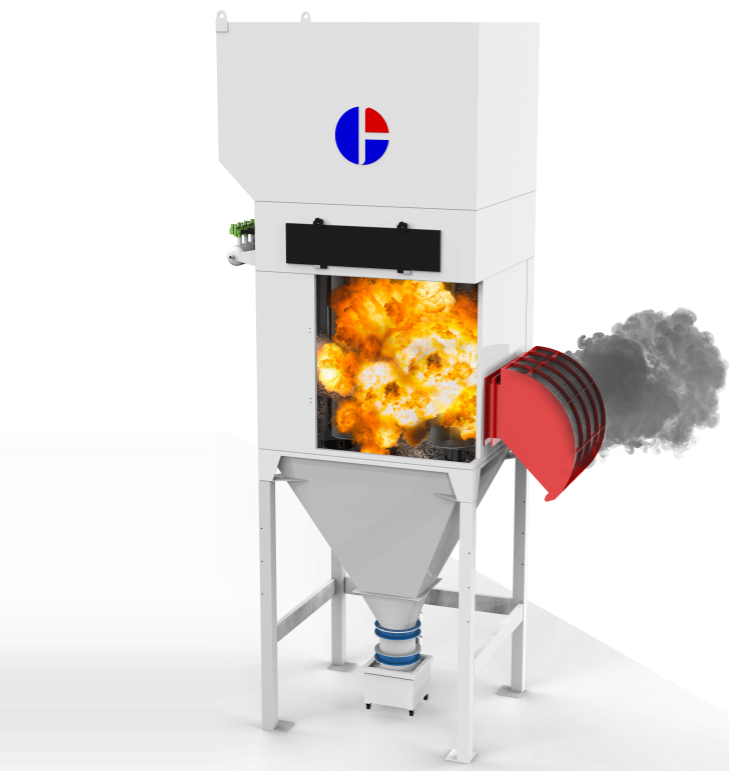

The Inogun series automatic spray guns have a universal base, which is easy and convenient to install. The spray guns can be installed and adjusted in different gears inside the spray booth according to actual needs. The adjustable flange at the rear of the spray gun allows the spray gun to be tilted to face the workpiece. The Inogun FCC version (fast color change version) can achieve fast color change due to its smooth drop-shaped gun body design.

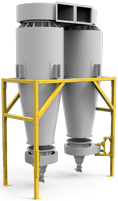

Saving powder and energy are the core of the research and development and manufacturing of spray guns to reduce waste emissions, improve production efficiency and the surface quality of the coating. The powerful high-pressure unit is matched with the high-pressure controller to produce a high embracing effect on large workpieces (diameter 200mm/7.8 inches) and penetrate the recessed areas of the workpiece. This greatly reduces the cost of equipment use, improves the efficiency of powder transfer, and reduces the work of pretreatment and manual touch-up. The smooth shape of the spray gun inside and outside makes color change more flexible and fast.

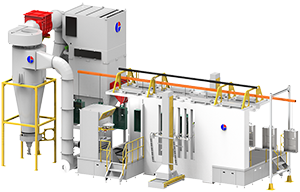

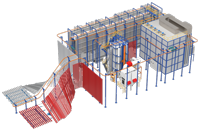

The Inogun automatic powder spray gun can be used in advanced powder processes or in very simple powder booths. The spray gun can be controlled by the built-in Inocontroller or the Inobox equipped with a clear and user-friendly operating interface. The Inobox or Inocontroller is the main control center in automatic applications and performs the high pressure and all gas flow control: high pressure, current, electrode blowing, injection and dilution air.